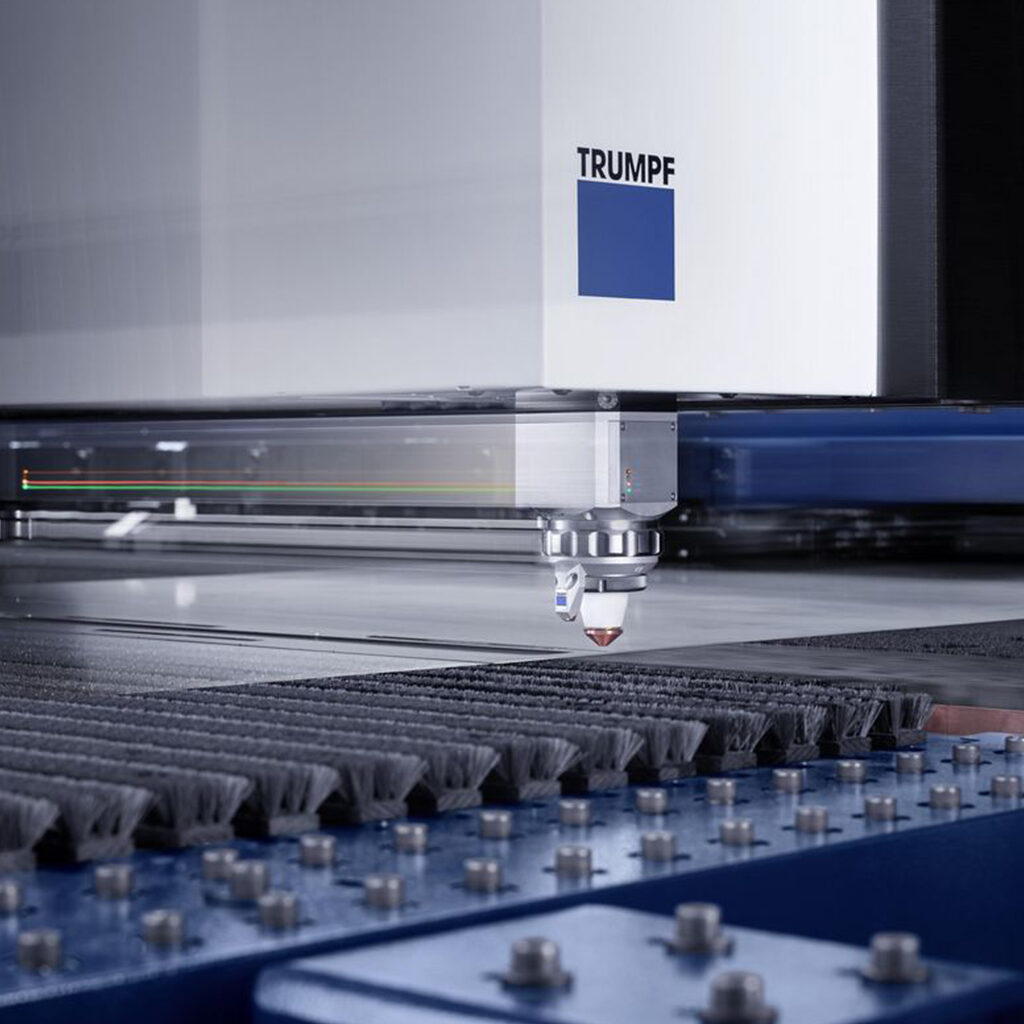

Wesgar follows through on its commitment to leverage state-of-the-art equipment in its world-class 100,000 square-foot Port Coquitlam plant with the addition of the new TRUMPF Fiber Laser. In support of Wesgar’s dedication to tailoring solutions that meet its customers’ complex needs, this unit is the first of many technology upgrades and additions planned for 2022.

“Customer demands for faster turnaround on quality products is greater than ever despite the current global pandemic,” says Nash Kassam, President of Wesgar. “The advantage of the TRUMPF Fiber Laser is its superior speed at cutting thin gauge metals, and we are already seeing a decrease of 40% to 60% in processing time. Increasing processing efficiency is critical to us meeting our customers’ deadlines.”

Wesgar specializes in end-to-end sheet metal and copper fabrication for high-mix, low-volume customers, operating around the clock as a cohesive team overseeing the dependable delivery of thousands of precision items manufactured in light gauge steel, aluminum, stainless steel, and copper. The new TRUMPF Fiber Laser will complement Wesgar’s existing $30M state-of-the-art sheet metal, machining, and copper fabrication equipment.

The onset of the global pandemic has significantly affected supply chains everywhere and increased the pressure on Wesgar to expand capacity, mitigate supply chain disruptions, and manage ever-changing production needs with agility. Its one-stop service strategy, commitment to improving processing efficiencies—with equipment such as the TRUMPF Fiber Laser—and dedication to best practices and continuous improvement allows Wesgar to deliver service excellence and quality finished products to customers exactly when they need it.