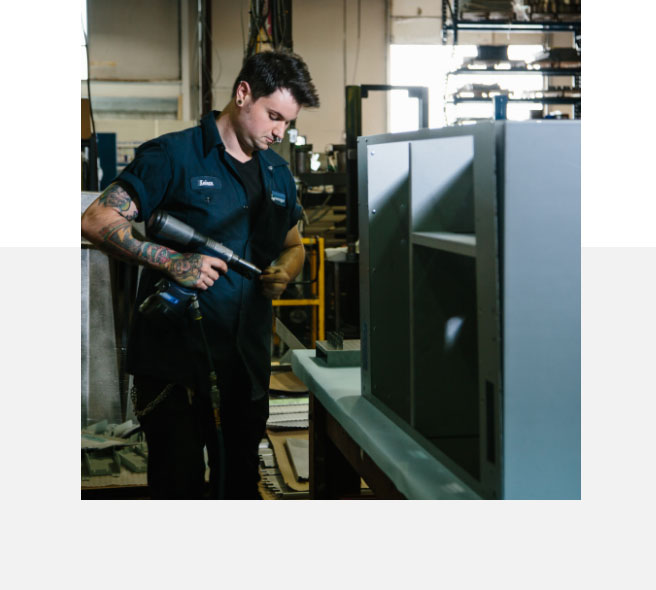

High-mix, variable-volume sheet metal fabrication specialists

As the largest producer of high-mix, variable-volume custom precision sheet metal products in Western Canada and the Pacific Northwest, Wesgar has a reputation for delivering an unparalleled service experience to every client. Our world-class, 80,000 square feet plant, located on our four-acre campus, is uniquely positioned as a one-stop shop, designed to meet your every need, from concept to a superior finished product.

Capacity, scalability, and performance

Wesgar has the capacity, experience, and ability to scale processes to take care of all your precision sheet metal fabrication needs—from simple, compact items to complex and large oversized units. Our unique design for manufacturability and prototype fabrication is a driving force that guarantees product excellence and is combined with custom fabrication and machining. Screen printing, powder coating and assembly, quality inspection and documentation, and superior inventory and logistics management—we take care of everything.

We understand the importance of delivering timely precision prototype parts in the design phase of your products and leverage our expertise and state-of-the-art machinery to meet your needs.

A system geared to solving problems

Our comprehensive integrated services and turnkey approach enables us to identify each of our customer’s unique challenges and complex needs and craft tailored solutions. For example, managing spikes and responding to variable demands, reducing cycle times, managing compound quality and technical requirements, lowering costs, and mitigating supply chain disruptions. We operate like the manufacturing arm of your business, allowing you to meet and deliver to your customers’ exacting standards.

Putting state-of-the-art technology and automation to work for you

We invest heavily in leading-edge technology—from manufacturing automation and robotics to robust engineering software—and this allows us to continuously improve processes and accuracy, lower costs, and meet your deadlines. Every month we deliver thousands of quality products to our discerning clients—crafted in light gauge steel, aluminum, stainless steel, and copper.

We understand the importance of delivering timely precision prototype parts in the design phase of your products and leverage our expertise and state-of-the-art machinery to meet your needs.

Diverse industry experience

Wesgar serves a diverse range of fast-growing industries, including energy storage and backup power systems, power distribution, OEMs, commercial electronics, telecommunications, medical, industrial and automation, clean and renewable energy, security, recreation, and more. Our industry experts are trained to meet the unique requirements of specific industries.

Wesgar values long-term customer relationships and is proud to count EnerSys, Rockwell Automation, Ballard Power, Kodak, HySecurity, Telus, Thompson Power Systems, and Honeywell, along with dozens of other respected organizations. Our customers, local and international, rely on us to deliver unrivaled responsiveness, collaborative engineering, innovative and accurate precision fabrication, and a flexible approach.

Rest assured, we’ve got all the bases covered

Highly certified and founded on a culture dedicated to best practices and continuous improvement; we bring problem-solving skills and 55+ years of experience to every project. Simply put, you can count on us to deliver exceptional quality and operational innovation, reduce the overall manufacturing cycle, solve supply management challenges creatively, lower costs and offer unbeatable value, and bring you personalized service—every time.