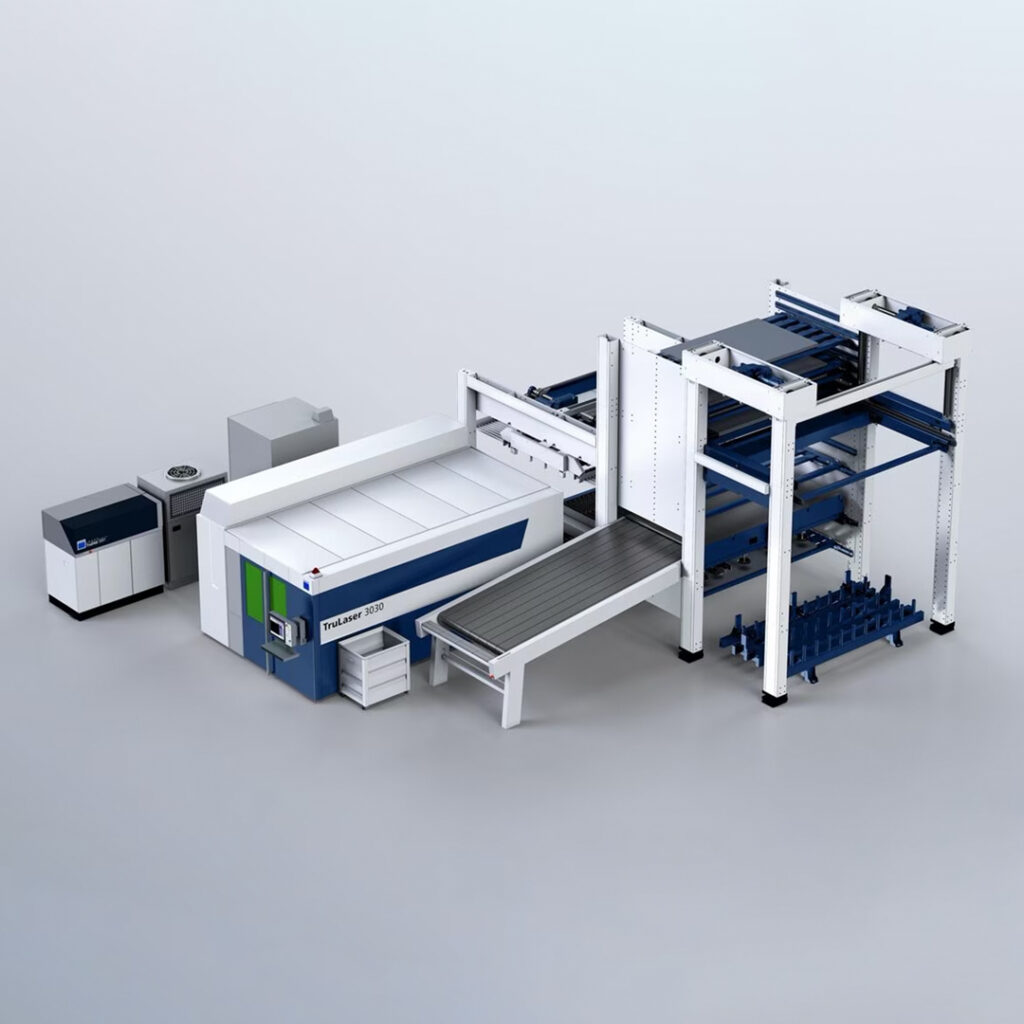

Wesgar has successfully installed the TRUMPF TruLaser 3031 Automation with LiftMaster to manage loading sheet metal more efficiently than ever onto its TRUMPF Fiber Laser. The addition of this state-of-the-art automation system ensures faster production turnarounds to keep pace with client demands.

“Maintaining our ability to increase capacity and throughput is a crucial part of making sure we can meet customer demands,” says Jeet Dhanda, Production Manager at Wesgar. “This new automation system removes the manual labor previously required to keep our fiber laser running—now fully operational, it can run for 16 to 22 hours with minimal supervision. This allows our operators to manage multiple projects simultaneously without compromising process reliability and speeds up the entire operation.”

The TruLaser 3031 Automation with LiftMaster is TRUMPF’s fastest and most compact loading and unloading unit. It’s a dynamic and variable automation solution that offers fast sheet processing and a short cycle time of 90 seconds.

“We believe that technology is a critical component of successfully growing our operation,” says Nash Kassam, President and CEO of Wesgar. ”To remain at the forefront of our industry, we’re investing heavily in adding technology wherever it meets our customers’ needs.”

Wesgar is the fastest-growing one-stop-shop precision sheet metal fabricator and the largest fabricator of high-mix, variable-volume complex products in Western Canada and the Pacific Northwest.