Better ways to mitigate supply chain issues

While COVID-19 might not officially be considered a pandemic anymore, there is little doubt that it has left its mark—probably for good. One significant way it has impacted the world is with supply chain issues. For company executives, the impact of supply chain disruption has highlighted vulnerabilities in their systems, which make them scramble to find ways to be more efficient.

In today’s economy, managers know they need to protect their supply chains from costly disruptions, especially since these disruptions have caused a domino effect on not just production but other areas of the company, ultimately affecting end users. The natural remedy in most cases would be to increase inventory or overstock; however, this only adds to bloated costs and undermines the efforts to improve supply chain efficiency. Thankfully, there are better ways to mitigate supply chain issues.

Reduce the concentration of your supply chain

Reducing the concentration of your supply chain and employing different suppliers to produce the same item is one way put redundancy into your system, reducing the likelihood of failure. For example, if one supplier runs into production issues, other suppliers can either take over or, at the very least, can still keep production flowing. Companies like Samsung always aim to have at least two suppliers, even if the second one provides only around 20% of the volume. This especially works well for the more in-demand products that need to be produced at higher volumes.

Pooling your resources

Pooling resources is another effective way to reduce supply chain disruption. This is effectively reducing the number of parts across different models or even across entire industries. By using more common parts instead of highly specialized parts, manufacturers can effectively mix and match or source elsewhere if there is disruption. In some cases, using the same part as a competitor might be beneficial; while it may reduce your product’s unique advantages, it might outweigh the downside if it ensures a customer gets their product delivered to them on time.

Use a Kanban system

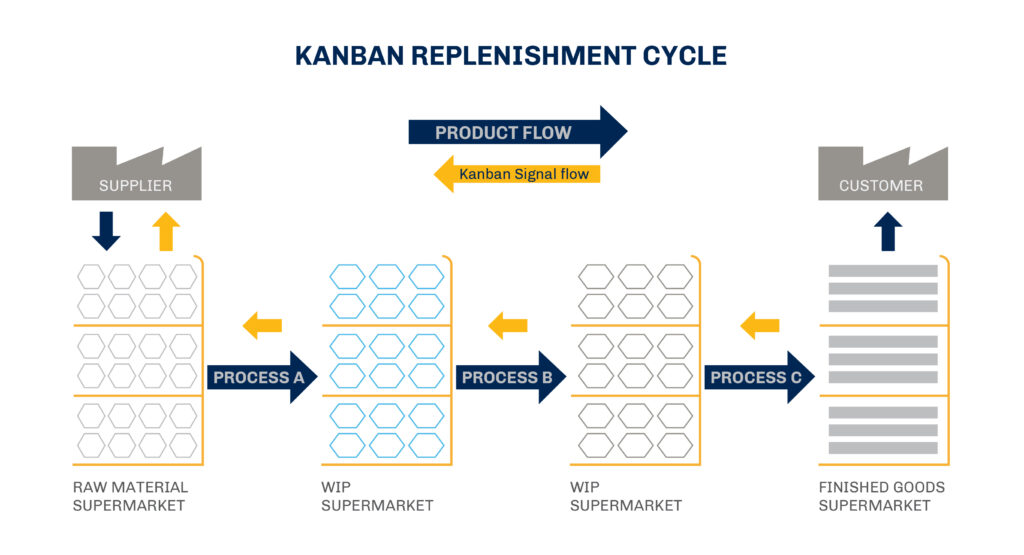

One way a company could streamline its supply chain, especially if it specializes in low-volume manufacturing, is to have better control over the visibility of its supply chain using a Kanban system. In basic terms, Kanban helps ensure you have the right stock at the right time. It helps to simplify and streamline the entire supply chain process from the moment an order is placed to the time it is delivered.

Kanban follows an agile framework that is interconnected and accurately measures all aspects of your supply chain system. By observing the frequency of orders and the time it takes to fulfill an order, a Kanban system can give managers the exact data they need to make the best decisions possible and stay flexible to meet the needs of the supply chain. Using Kanban can also help highlight manufacturing efficiencies, staffing levels, or the demand level of a certain product.

Do a risk assessment analysis of your supply chain

Although it’s impossible to estimate the probability of the bankruptcy of a supplier, a natural disaster, or a faulty component, managers can do a risk assessment and look for potential weak spots in their supply chain. By looking at different scenarios, managers can estimate the expected impact of an incident if and when it occurs. Being proactive and making choices to mitigate those risks can sometimes help save millions of dollars.

How to respond to supply chain disruption

Businesses must navigate the impact of a world where the supply chain has become increasingly fragile. By taking the right actions, executives can turn massively complex supply chains into a more efficient and agile system.

Companies must also respond to the lasting impacts of the pandemic and prepare for what comes next by ensuring there is a continuous cycle of managing, analyzing, and configuring operations, which will help to optimize their supply chain and mitigate future risks.

Wesgar can help with sheet metal, machining, and copper bus bar fabrication to mitigate supply chain disruption

If you’re frustrated with your supply chain and aren’t getting the results you want, Wesgar, located in British Columbia, can help. We are the largest producer of custom precision sheet metal products in Western Canada and the Pacific Northwest. Contact us today.