What is a bus bar?

An electrical or grounding bus bar is the backbone of an electrical distribution network, connecting various electrical devices, such as transformers, switchgear, and circuit breakers, and distributing energy to different parts of an entire system. The selection of the right bus bar system is crucial for ensuring efficient and reliable electrical energy distribution in industrial, commercial, and residential settings.

How to design and select electrical bus bars

The mechanical requirements of a bus bar are a technical matter that require an expert. However, there are several key factors to consider when choosing a suitable bus bar system for your needs. One of the most important is cost—different types of bus bars have different price points and trade-offs in terms of performance and reliability. Due to the dangers of overheating, bus bars aren’t something you want to try and cut corners on.

Your engineering expert will want to look at the following aspects:

Current rating:

This determines the maximum amount of current that the bus bar can safely carry without overheating. The higher the current rating, the more power it can handle.

Voltage rating:

This affects its ability to distribute electrical energy to connected devices. The higher the voltage rating, the more distance it can cover.

Strength and stability:

This refers to how well the bus bar components can withstand mechanical stress and environmental factors, such as rain, snow, and corrosion.

Electrical bus bar sizes and types

Depending on your system, bus bars come in many sizes, starting from as small as 1.6 x .15 inches. Additionally, there are several different types of bus bar systems available on the market, each with its own unique set of advantages and disadvantages. Some common types are as follows:

Single bus-bar:

This is a simple and easy arrangement that consists of a single bus with a switchboard. It is cheap and flexible, but it has low reliability and security.

Double bus-bar:

This consists of two parallel buses with two circuit breakers for each device. It has high reliability and security, but it is expensive and complex.

Ring bus-bar:

This forms a closed loop with one circuit breaker for each device. It has moderate reliability and security, but it has low flexibility.

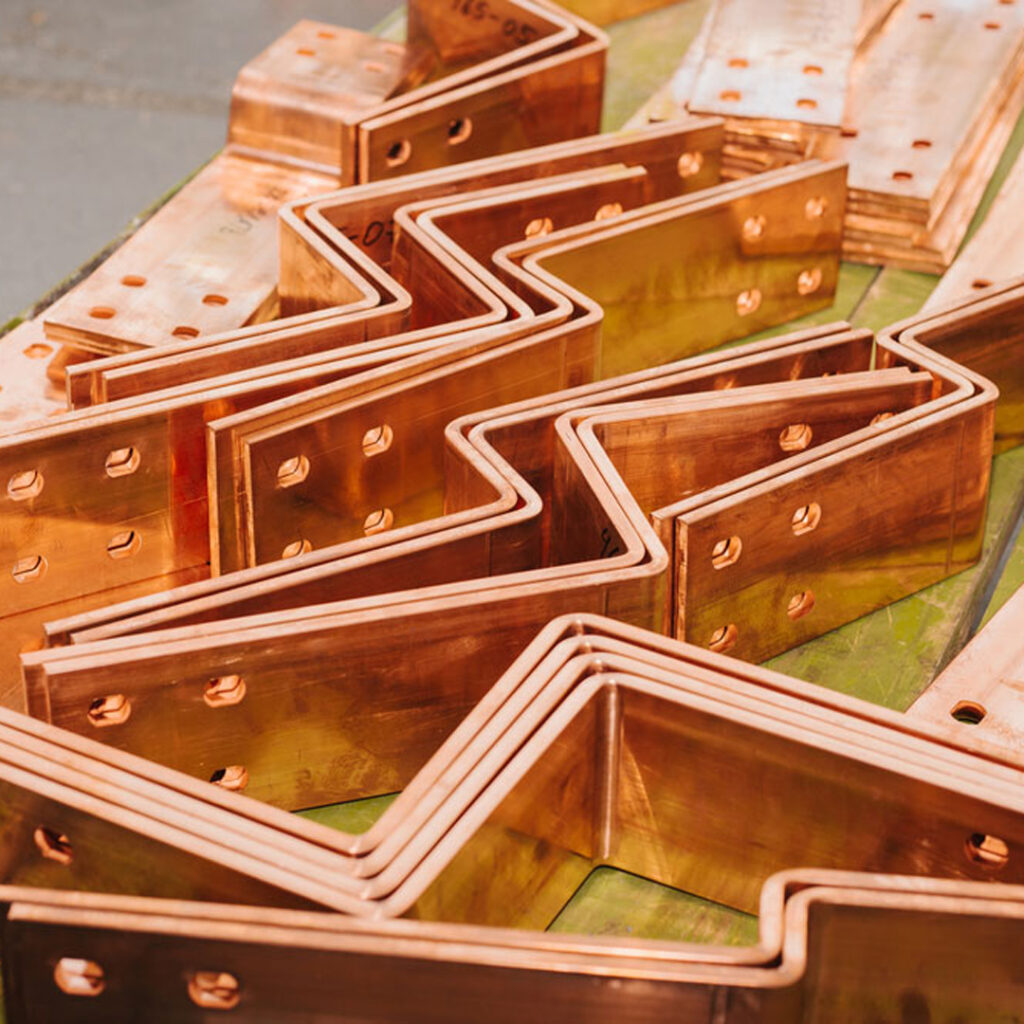

What are bus bars made of?

Copper bus bars are the most popular choice due to their high conductivity, low resistance, and relative durability compared to other materials. Copper can carry more current than aluminium or brass with less heat loss and voltage drop. Copper also has good corrosion resistance and mechanical strength.

Aluminum bus bars are also an option due to their lightweight and high thermal conductivity as well as silver, which has high conductivity and low resistance, making it ideal in high-voltage applications, where weight and space are critical considerations. However, since silver is expensive, it is also the most costly option.

Bus bar maintenance

Bus bars require regular maintenance to ensure safe and efficient operation. This includes regular inspections to check for signs of damage or corrosion, cleaning the surface of the bus bar to maintain its conductivity, tightening connections between the bus bar and other electrical components, replacing any damaged components, and testing the bus bar to ensure that it is operating within its specified limits.

Regular maintenance should be scheduled. By performing maintenance, you can help to extend the life of your bus bars and ensure they continue to provide reliable electrical energy distribution for your electrical distribution network.

Bus bars—in summary

Choosing the right type of electrical or grounding bus bar system is essential for ensuring efficient and reliable electrical energy distribution in any setting. We recommend you consult an expert to help you design and select the best option for your needs based on cost, performance, reliability, strength, stability, size, material type, shape, current rating, and voltage rating.

Wesgar manufactures high-quality copper bus bars

If you are looking for quality copper products that meet international standards, contact Wesgar today. Wesgar offers competitive prices, fast delivery, quality copper, hi-mix low-volume runs, excellent customer service, and inventory stocking programs.